News

-

How is the global cellulose ether development?

According to the latest report from IHS Markit, the global consumption of cellulose ether—a water-soluble polymer produced by chemical modification of cellulose—is close to 1.1 million tons in 2018. Of the total global cellulose ether production in 2018, 43% came from Asia (China accounted for 79...Read more -

How is methyl hydroxyethyl cellulose prepared?

Background and Overview Cellulose ether is a widely used polymer fine chemical material made from natural polymer cellulose through chemical treatment. After the manufacture of cellulose nitrate and cellulose acetate in the 19th century, chemists have developed a series of cellulose derivatives o...Read more -

How is hydroxyethyl cellulose prepared?

Hydroxyethyl cellulose is an important cellulose derivative. Due to the advantages of abundant raw material resources, renewable, biodegradable, non-toxic, good biocompatibility, and large yield, its research and application have attracted much attention. . Viscosity value is a very important per...Read more -

How does cellulose in mortar play its role in water retention

In the production of building materials, especially dry powder mortar, cellulose ether plays an important role, especially in the production of special mortar (modified mortar), it is an important component. The important role of water-soluble cellulose ether in mortar is mainly its excellent wat...Read more -

What is the effect of “tackifier” on cellulose ether in mortar?

Cellulose ether, especially hydroxypropyl methylcellulose ether (HPMC) is an important component in commercial mortar. For cellulose ether, its viscosity is an important indicator that mortar manufacturers pay attention to, and high viscosity has almost become the basic demand of the mortar indus...Read more -

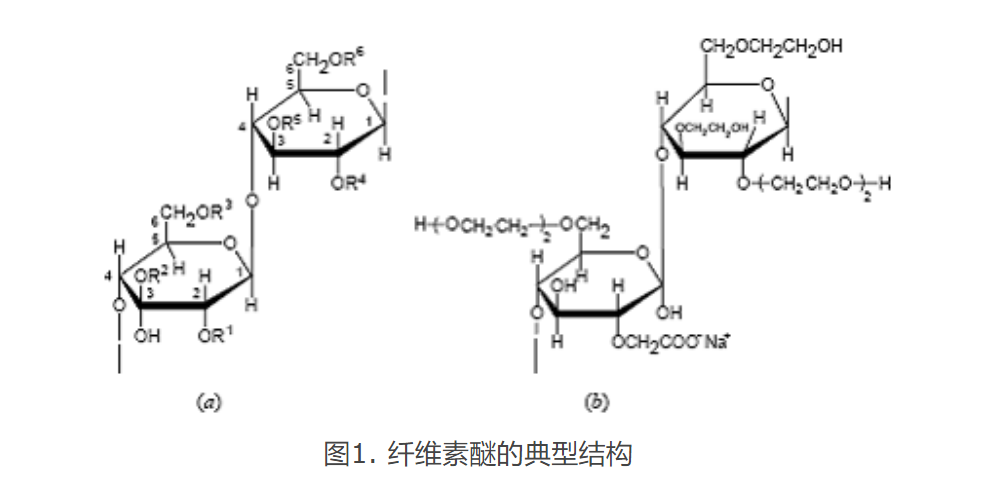

What are the structures and types of cellulose ethers?

1.Structure and preparation principle of cellulose ether Figure 1 shows the typical structure of cellulose ethers. Each b-D-anhydroglucose unit (the repeating unit of cellulose) replaces one group at the C (2), C (3) and C (6) positions, that is, there can be up to three ether groups. Due to the ...Read more -

The quality of cellulose ether determines the quality of mortar

In ready-mixed mortar, the addition amount of cellulose ether is very low, but it can significantly improve the performance of wet mortar, and it is a main additive that affects the construction performance of mortar. Reasonable selection of cellulose ethers of different varieties, different visc...Read more -

How is the development of cellulose ether?

Industry chain situation: (1) Upstream industry The main raw materials required for the production of cellulose ether include refined cotton (or wood pulp) and some common chemical solvents, such as propylene oxide, methyl chloride, liquid caustic soda, caustic soda, ethylene oxide, toluene and ...Read more -

Coating formula raw material analysis

Hydroxyethyl Cellulose Ether Hydroxyethyl cellulose ether, a non-ionic surface active substance, is a commonly used cellulose ether organic water-based ink thickener. It is a water-soluble non-ionic compound and has good thickening ability to water. It has many characteristics such as thickening,...Read more -

Various Applications of Cellulose Ether

1. Cellulose ether products used in tile adhesives As a functional decorative material, ceramic tiles have been widely used all over the world, and how to paste this durable material to make it safe and durable has always been a concern of people. The emergence of ceramic tile adhesives, in To a ...Read more -

How is sodium carboxymethylcellulose prepared?

Using cellulose as raw material, CMC-Na was prepared by a two-step method. The first is the alkalization process of cellulose. The cellulose reacts with sodium hydroxide to generate alkali cellulose, and then the alkali cellulose reacts with chloroacetic acid to generate CMC-Na, which is called e...Read more -

The quality of cellulose determines the quality of mortar

In ready-mixed mortar, the addition amount of cellulose ether is very low, but it can significantly improve the performance of wet mortar, and it is a main additive that affects the construction performance of mortar. Reasonable selection of cellulose ethers of different varieties, different visc...Read more